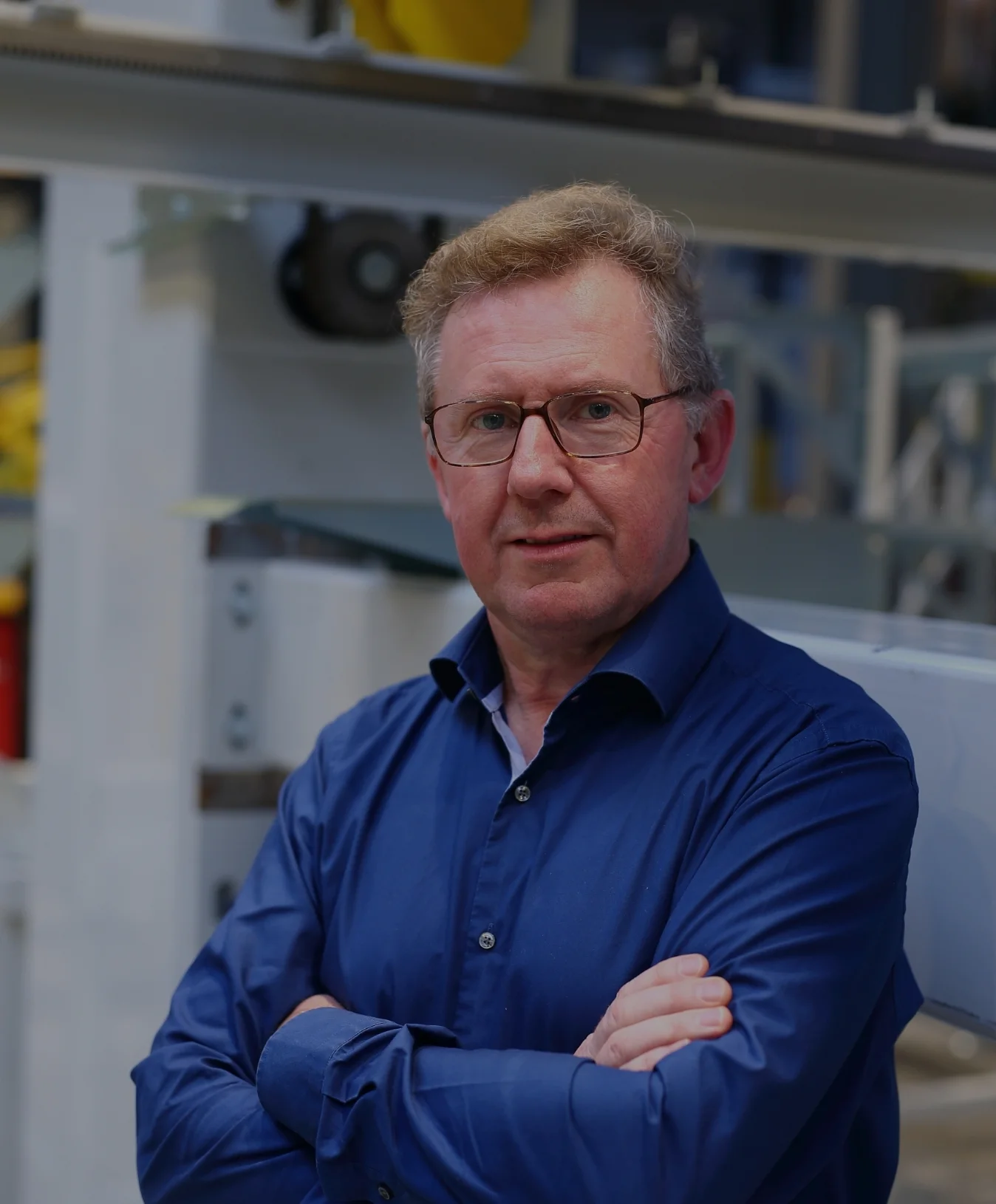

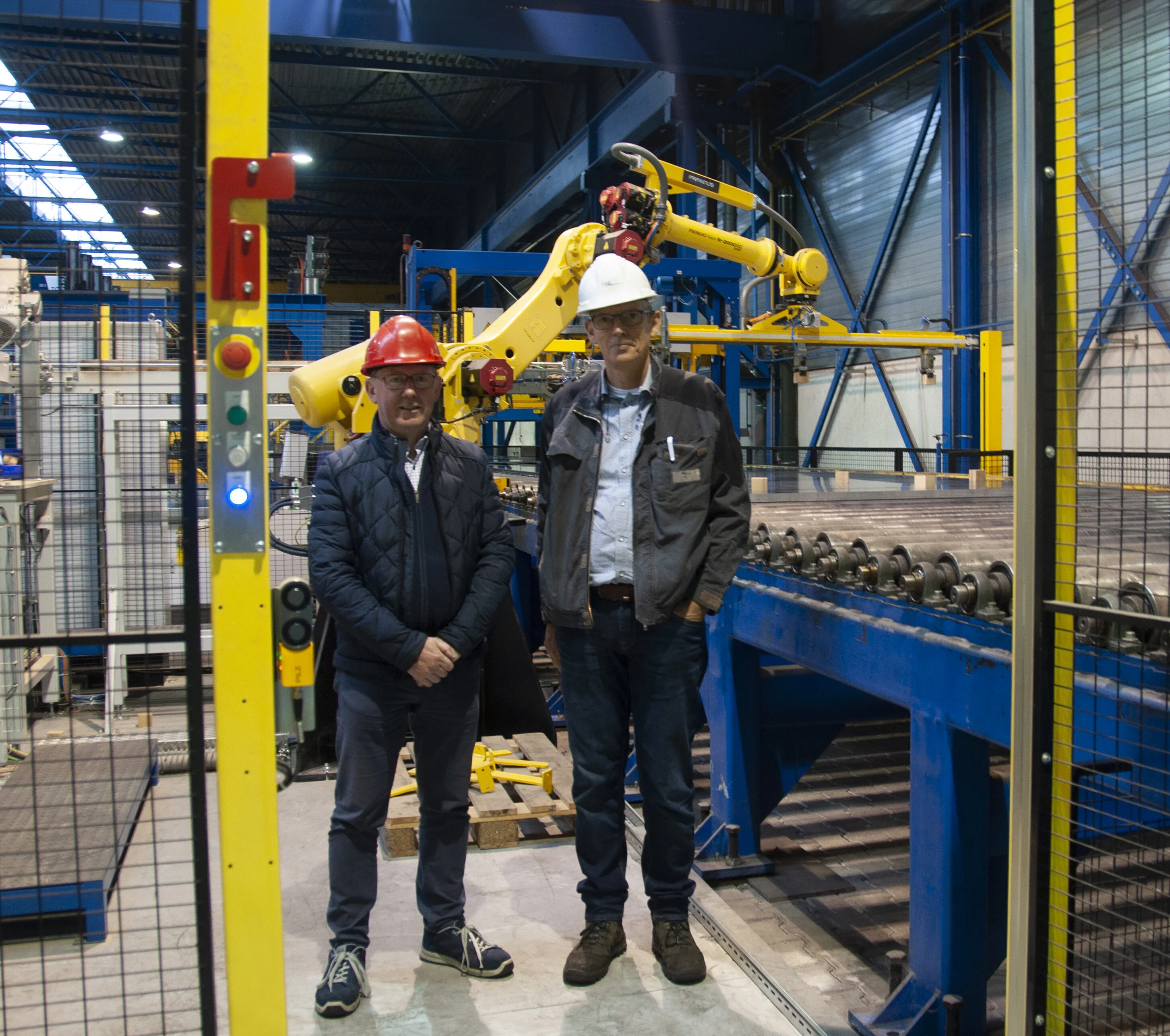

1 | THE TASK

During the first stage, we sit down together to outline the project. What needs to happen? Where will the challenges lie? Preparation is key – we can’t afford to be slack at this stage! If necessary, we’ll underpin the exploration with a preliminary study using 3D modelling.