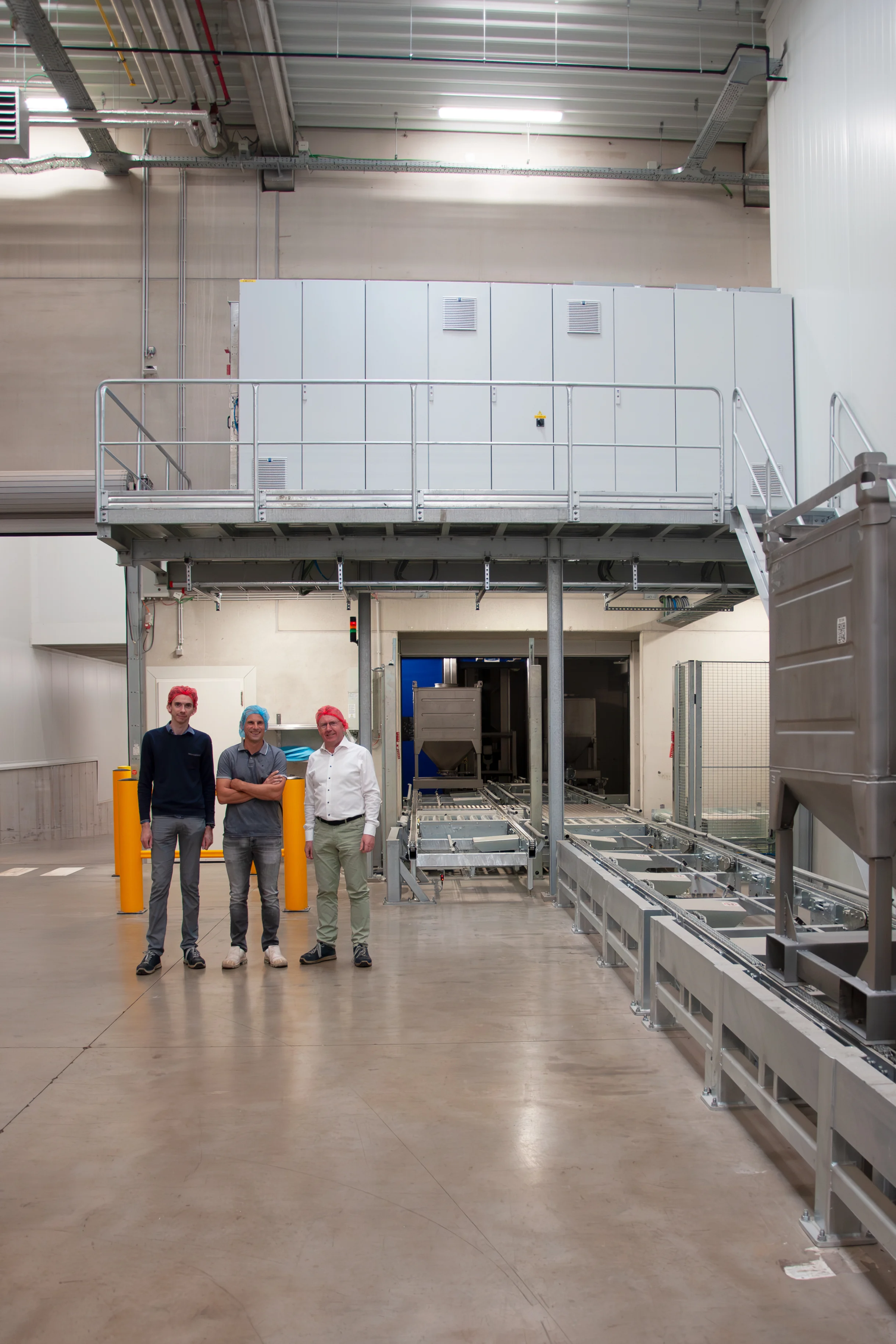

“The installation at Clarys is a technically challenging line, realised within an existing building that was never designed for heavy machinery. Raw materials from the warehouse (pallets with bags or big bags) are transported via several routes to discharge zones where stainless-steel containers are filled. Due to an intermediate level, available height was limited, meaning the lift systems had to be partially built into the floor, which made the layout particularly complex.

A floor that was too light for machinery was removed and, together with Stumaco, replaced by stainless-steel platforms. From the transfer trolley to the discharge zones, everything is built in stainless steel, suitable for cleaning with water.

The upstream supply sections are made of galvanised steel. A roller curtain separates the dry area whenever the stainless-steel zone is being cleaned.

On level 0, a long roller conveyor buffers pallets. A barcode scan on the lift determines whether a pallet goes straight ahead to the discharge points, moves upwards, or gets sent back. There’s also an emergency function to send a pallet directly up. Empty containers enter here and are distributed via a shuttle to two container lifts with integrated weigh cells. A fixed cleaning container collects rinse water and drains it automatically, preventing contamination.

On level 1, pallets arrive on a transfer carriage with three destinations:

- Big bag discharge: big bags are hoisted manually from the pallet and placed on a discharge station. The product flows dust-free via a rotor and sieve into the container.

- Automatic discharge (bags): a lift brings the pallet to an ergonomic working height. The bags are placed on a belt, automatically opened and discharged while the contents fall through a rotor and sieve into the container. This was an existing machine, now integrated into the control and safety system.

- Manual discharge (level 2): pallets with collars are transported via a separate lift to the upper level, where chain conveyors and two discharge hoppers are installed. Operators empty the bags manually here.

The entire process required nearly a year of preparation. Everything was modelled in 3D in advance to clearly visualise the flow within the limited heights, narrow buffer zones and strict hygiene areas. The result is a traceable, safe and easy-to-clean installation – installed in a building that was never originally intended for this purpose.”

- by Alexander Priem

sales engineer