A LOOK BACK ON THE COLLABORATION WITH FRAXINUS

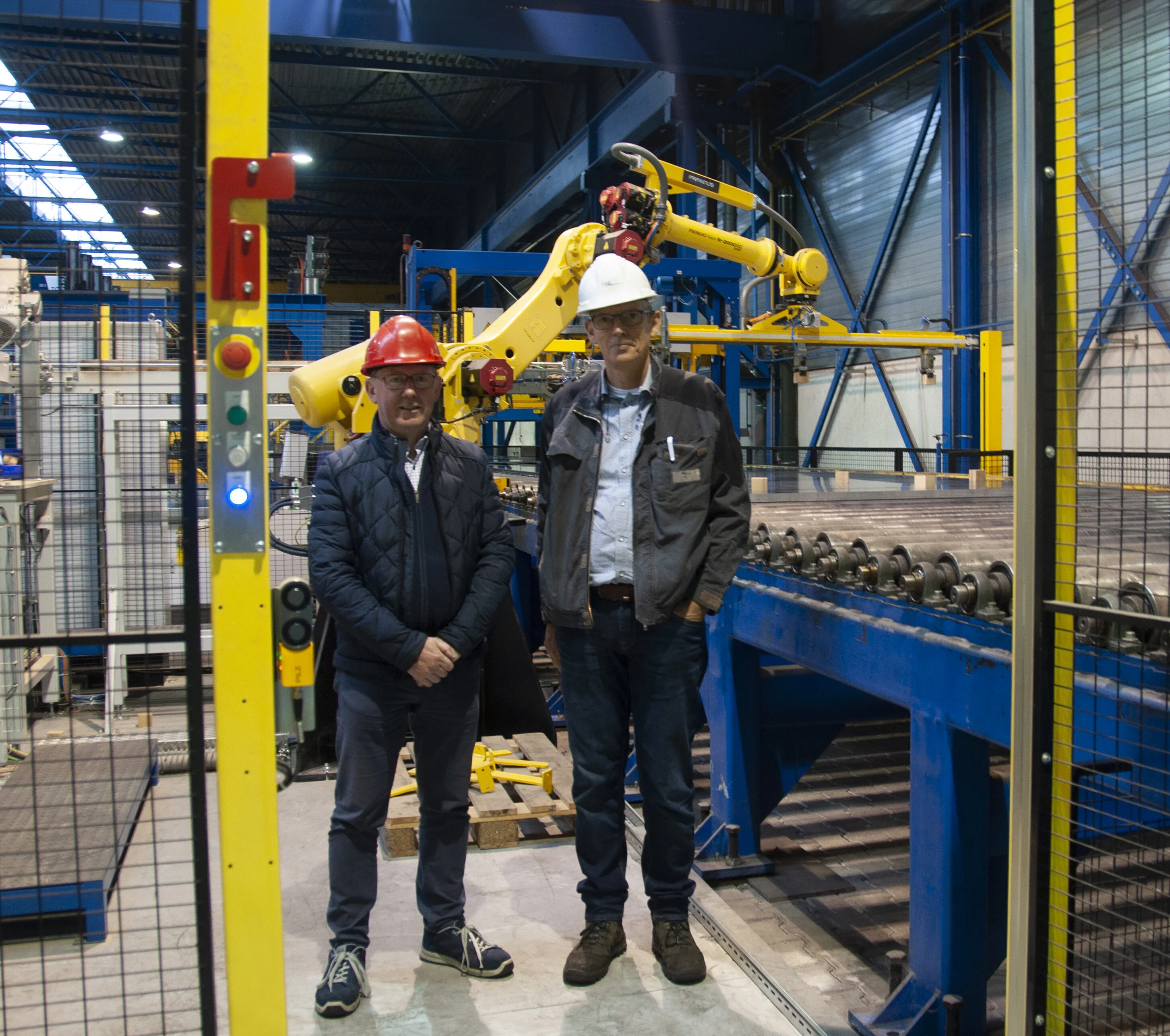

Edwin : “We instantly knew that we were in good hands with Fraxinus, which would supply the best possible technical solution. The first proposal not only took our current requirements into account, but also our future needs: for example, switching from cubes to bars in the long term is perfectly possible. The engineering team built a test set-up that we could assess on site, before the machine was installed in our warehouse. During the run-in period, a number of minor adjustments were needed to ensure a smoother flow.

The cooperation with the programmers also went very smoothly. We can always call on Tim’s help, who can log into the system remotely to set new parameters if necessary. This way, we are always reassured that technical problems can be solved quickly. Fraxinus is highly recommended if you are considering logistics automation!”