“At ODTH in Rumst, an existing warehouse is being transformed in five phases into an automated shuttle system from Movu, built within racking supplied by Stow. In total, the project will add around 31,000 pallet spaces. The biggest challenge: working in a live warehouse without halting operations.

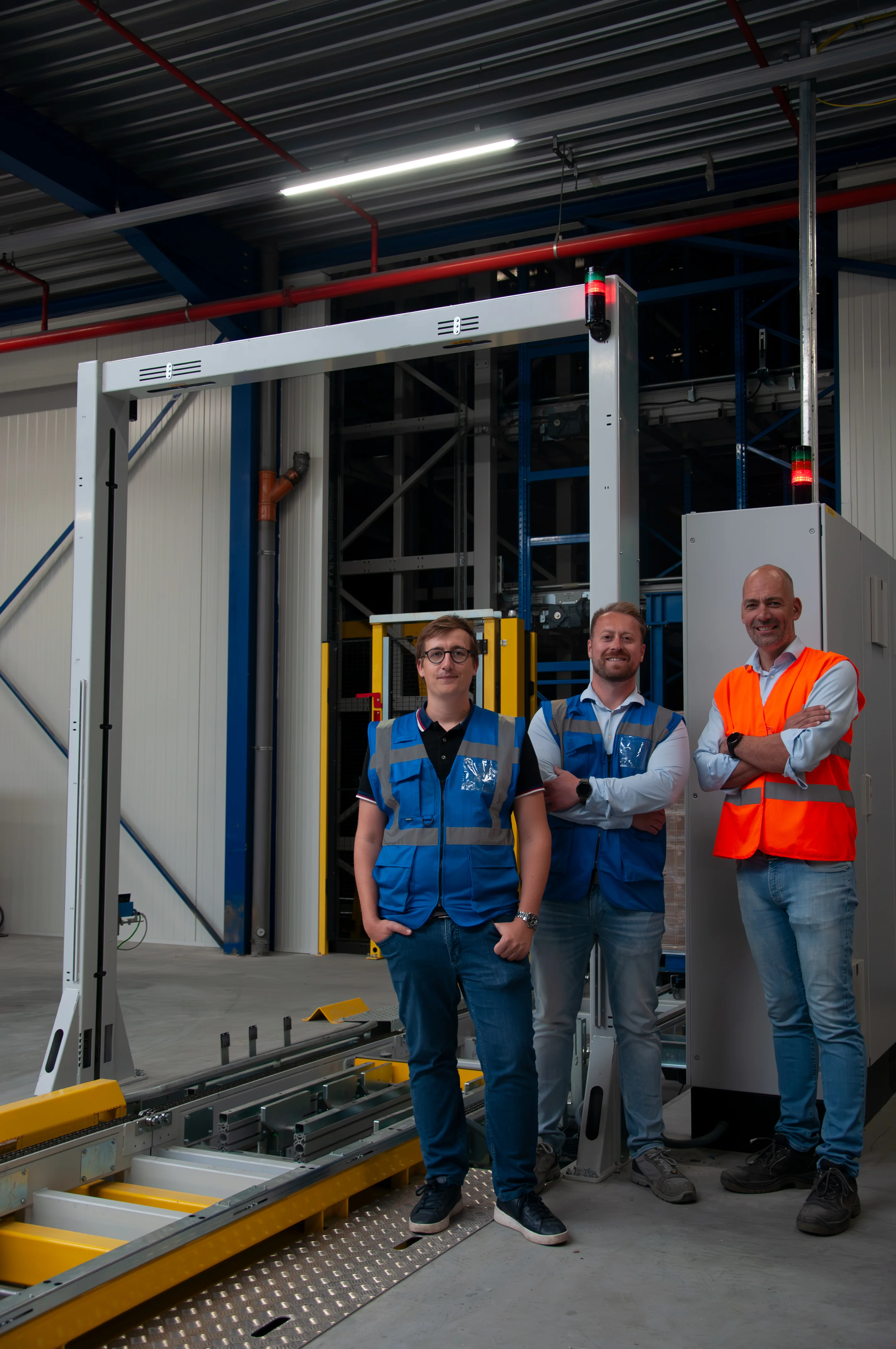

Fraxinus developed all in- and outbound systems. Pallets enter via conveyors, are automatically measured, scanned and subjected to a gabarit check. Compliant pallets proceed to inbound; any deviations are diverted to a manual line.

From the inbound conveyors, pallets travel via vertical lifts to the correct level. The lifts are designed to transport shuttles as well, allowing capacity to be flexibly distributed. The shuttles store pallets in the racks and retrieve them for outbound transport. Conveyors then move the pallets to the expedition zones, where a connection has been created to the existing rapid-loading system. This buffers pallets and arranges them in sequence for efficient truck loading. A retrofit of this system is planned in a later phase.

The warehouse was originally filled with old Stow racking and manual Movu units. These were dismantled block by block; the steel was recovered and reused in the new installation, saving over 680 tonnes of CO2. A central cube structure was retained in the middle of the site, introducing additional height variations and complexity in construction. Fire safety requirements added to the challenge: all zones are enclosed and fitted with liquid containment curbs, even beneath conveyors. This demanded precise integration and close coordination throughout every phase.

In addition to the mechanical systems, Fraxinus supplied the complete cabling and control system installation, including safety features such as fencing, signalling and access detection. The system processes 2,500 to 3,000 inbound and outbound pallets per day, and provides a total of 10,000 extra pallet positions.”

- by Ryan Debacker

project engineer